For the past two weeks, I’ve been investigating whether it’s possible to 3D print clothing. I’ve discovered a lot about the world of textiles and think there’s an opportunity worth pursuing here if I can find the correct strategy. I’m going to give a little background on computational knitting first, then go into the first of several different possible strategies.

If you’ve been following my Instagram exploration, you already know what’s coming. But! I’ve got a couple more observations to add on at the end.

Why 3D Print Clothing?

In the current centralized manufacturing system, we incentivize a race to the bottom on cost (inadvertently causing bad side effects like sweatshops), incur massive waste from the inability to match supply to demand, and cause geopolitical tension from imbalanced production/consumption at a country-level (e.g. disproportional US imports from China).

These issues could be addressed with localized manufacturing. Theoretically, a perfect molecular printer would give everyone the ability to economically manufacture anything within their home. It would not only drastically improve the world on a macro scale (enhancing productivity, decoupling supply chains, improving independence), but also tangibly improve people’s everyday lives (more control over the products they own, faster resolution of needs).

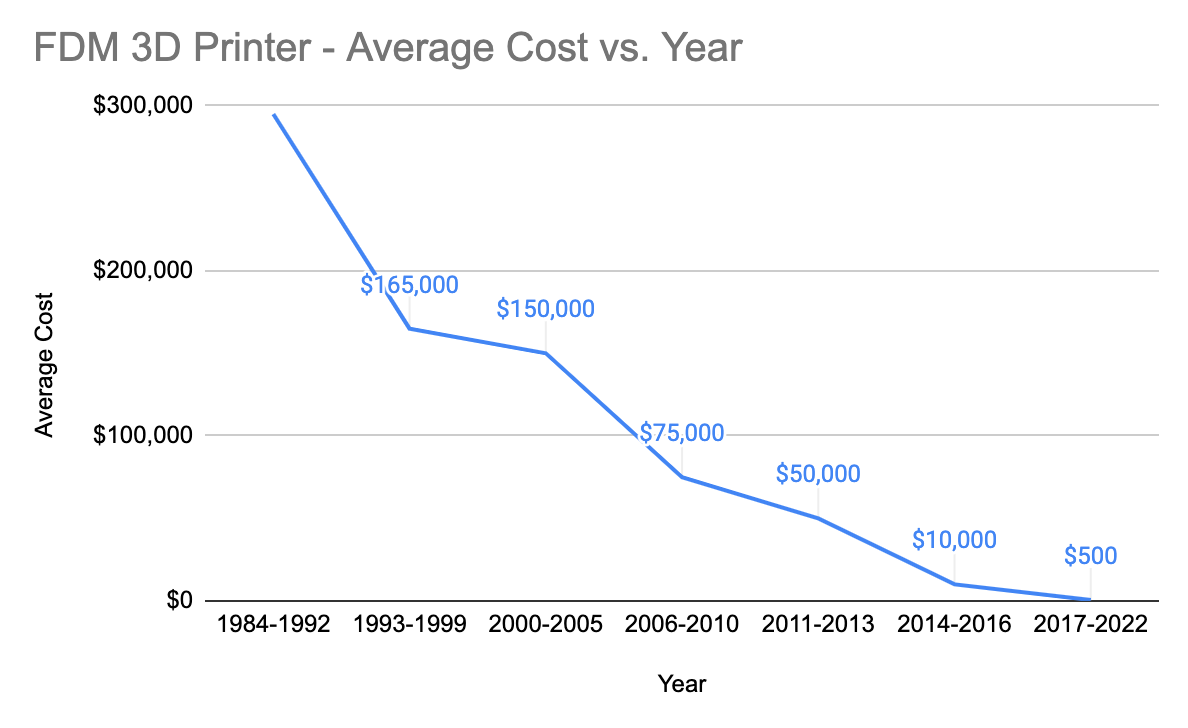

Up until now, 3D printing has promised to enable this revolution but failed to deliver. Since we can only print plastics, its applicability in real world use is limited. While the machines have become remarkably economical ($100-300) over time, they still don’t encompass the set of use cases that would really drive adoption.

I think the real thing we’re missing is multi-material printing; for example, being able to print consumer electronics by printing plastic, rubber, metal, all in one go. There are some interesting developments on this front, but it’s all still very expensive and very experimental. I think it’s going to be a long time until we can achieve that level of capability, then another long time until consumer adoption.

This got me thinking along a different route. Maybe there is a way to achieve this but only in one industry? What’s something that people consume significant quantities of, but only uses one type of material? Clothing. Is it possible to 3D print clothing? Sorta.

People have tried using FDM printing a couple times, and the results have always been iffy:

The designs look cool and futuristic, but nobody wants to wear plastic that’s impossible to put on, and cracks the moment you sit down. Also, plastic isn’t warm.

Is there another way, though? Yes - Computational Knitting.

What is Computational Knitting?

Before we get into this, we have to take a step back and understand textiles. There are two main ways to manufacture fabric: weaving and knitting.

Weaving

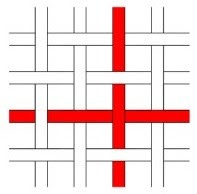

Woven materials look like this:

They’re many different yarns intertwined in the X/Y directions to create a fabric. You only get stretch from the fiber itself, so woven clothing is typically not very stretchy unless it’s made of something like elastane. Examples of woven clothing include: denim, corduroy, and dress shirts.

The automation machine for weaving is the loom, which does this grid interleaving automatically. Looms produce panels of fabric, which you have to cut and sew into clothing, meaning postproduction cost is high.

Fun fact: the loom was actually the inspiration for the first punch card computer, because the first automated looms were “programmed” with punch cards.

Knitting

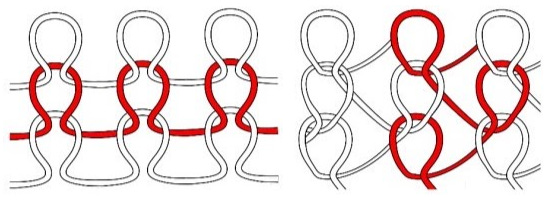

Knitted materials are entirely a single yarn intertwined in a complex pattern. The two main types of knitting patterns are weft and warp:

Knitting patterns are unique in that they allow significantly more stretch than woven materials purely because of the interleaving pattern, are wrinkle resistant, and critically can create contours. Because of this contouring property, an entire piece of clothing can be knitted at once with very little post-processing required. This means it’s got great automation potential.

Examples of knitted clothing include: sweaters, t-shirts, leggings, and underwear.

Automation of knitting has come a long way since hand knitting was invented in ancient times (for a sense of time scale, they found knitted socks in the Egyptian pyramids). The first knitting machine, called the stocking frame, was invented in 1589. it played an important part in the industrial revolution, mechanizing the textile industry. It had to be used manually and there was no way to program a design, but it still sped up knitting by an order of magnitude.

How does it work? At a very basic level, a needle pulls a thread, makes a loop, and builds a dependency chain of loops. At the scale of an entire machine, tons of needles do this in parallel to print a clothing item layer by layer:

To tie this back to the original question: what is computational knitting? Pretty much, we can generate machine instructions that cause a knitting machine to output contours that precisely match any shape or piece of clothing.

So, what’s the state of the art?

Hardware

Knitting machines today have come a long way, but only on the enterprise side.

There’s a single company that’s monopolized the space called Shima Seiki. They make programmable machines that can print a sweater in 30 minutes. Their machine is extremely advanced, with multiple sets of hooks in different arrangements allowing for all kinds of advanced knitting operations.

Their machines cost around $165k, so quite pricey. But, this company is one of the driving forces behind athleisure today - it has partnerships with Nike and Adidas to make Fly-knit sneakers, seamless leggings, etc.

However, since the industry is beginning to see computational knitting as the next big thing after early successes, a lot of other companies are churning out innovations on this front. After reading through a ton of showcases from ITMA 2019 (the big international textile machine conference that happens every 4 years), I found at least 5 other big companies trying to create advanced computational knitting machines.

On the consumer end, knitting machines are reasonably priced ($200-2000) but all must be used manually and none offer programmability. Some literally still use punch cards. There’s a startup called Kniterate that Kickstarter’d a consumer programmable knitting machine targeting the $5000 price point, but they’ve since had huge delays (3 years late) and the price point has risen to $16,000.

Software

From what I can tell, the state of the art in knitting machine software is utter garbage. Shima Seiki has their own proprietary software for creating patterns, simulating end results, and generating machine code. It’s probably the best there is, which is not great. The Kniterate team is making their own version as well, but it similarly looks quite clunky.

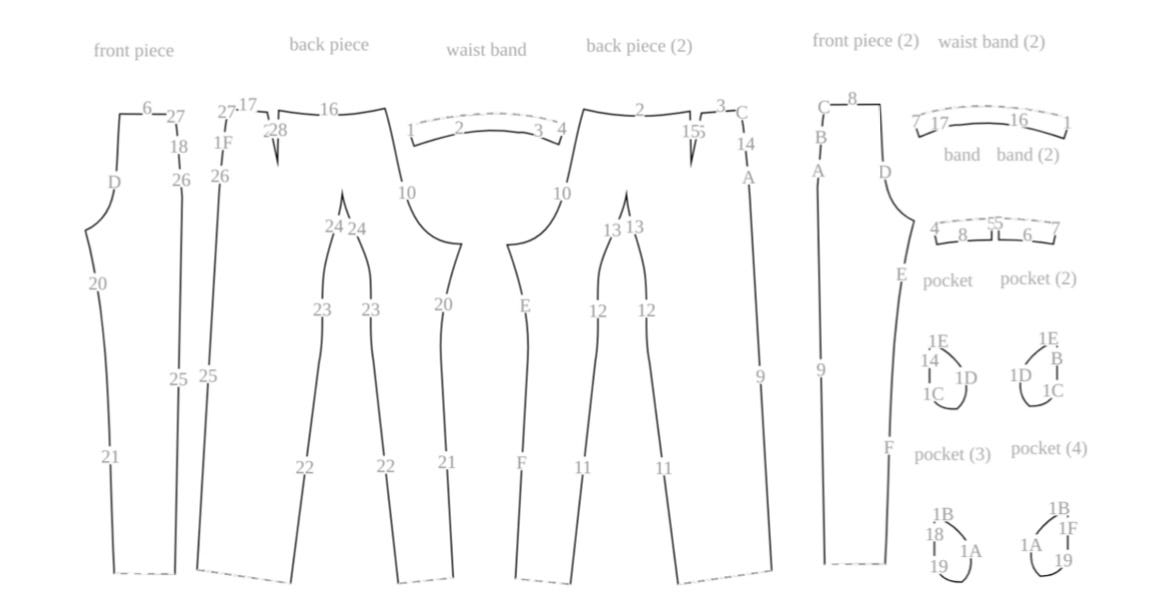

Clothing designers today use 2D paper or digital drawings of designs, which they mentally transpose into a 3D shape. They compile all these 2D drawings, measurements, and notes into a PDF that they call a “techpack”, which the manufacturer is expected to correctly execute on. There’s a company called Techpacker that appears to be trying to move this process online without changing the core steps. This seems completely absurd; how is there not CAD for clothing design yet?

Here’s what I think the solution space of knitting software contains:

Creating 2D clothing blueprints

Simulating 3D clothing shapes based on these blueprints

Generating knitting patterns from the blueprints

Fine-tuning knitting patterns manually

Directly manipulating 3D clothing shapes

Simulating clothing drape on different body models

Automatically form fitting to specific body models

Scanning body measurements as an input to the above step

Generating machine code for knitting machines

Here’s something interesting: the cutting edge of computational knitting software has progressed significantly in the last 5 years, driven by research labs at MIT and CMU.

For example, Disney Research recently published a joint paper with UC, MIT, CMU creating a compiler for knitting. It takes 2D patterns and spits out machine code for knitting machines, enabling access to programmable knitting on more machines.

So, that’s the crash course on the landscape of clothing production and machine knitting. Let’s talk opportunities!

Business Plan - Direct to Consumer

Here are my overly optimistic claims:

Knitting machines will be the first mass adoption use case for localized manufacturing

Knitting machines can be driven down to a consumer level price point ($500-5k)

Consumer knitting machines can be made user friendly and reliable enough for mass market consumers

Consumer knitting machines will expand in capability to encompass 50% of all clothing items and materials

Knitting software can be made widely accessible and easy to use, unlocking clothing design tools for the masses

Everyone will own a knitting machine, and print their own clothing

Overarching Strategy

My main thesis is that 3D knitting hardware is improving, but not quite there. It will require capital and time to push it over the edge. But, how do we start small, then incrementally build up an R&D flywheel that will become unstoppable at scale? A prudent way to approach this would be: sell something from the get-go. Sell what? 3D knitted clothing. Essentially, we start a fashion brand.

Phase 1

We follow the top-down model: sell luxury products first, then move down the price range as scale increases. For this phase, we only sell clothing, not machines. We can take advantage of key technological edges to out-perform all key competitors:

Online only

Sell everything made to measure

Act on fast fashion trends in a matter of hours vs days

Play sustainability and localized manufacturing into branding power

Partner with famous designers to drive sales and establish branding

Reinvest revenue back into R&D for driving down the cost of 3D knitting machines

Key software development at this phase:

Algorithmic M2M

Body scanning app

Phase 2

Open brick and mortar stores to improve branding, give access to body scanning tools, allow people to touch fabrics before they buy, and witness the items being printed in the store.

Expand catalogue of clothes to several different types of items

Continue to reinvest revenue into R&D

Key software development at this phase:

Online UI for knitted clothing design

Phase 3+

Begin to sell the machines when price point is achieved - can be sold at cost or for a loss

Reinvest revenue back into improving machines, further driving cost down and increasing capabilities (different materials, different clothing features)

Gradually expand catalogue of items from high end to all clothing items

Ultimately: own the entire supply chain for world wide fashion. Brands will use our supply chain to deploy their designs

Key software development at this phase:

Online marketplace for designs

Competition

Market sizing

Global Fast Fashion

$20B TAM 2020 -> $40B 2025

Global M2M

$1B TAM (SWAG guess)

Global Apparel

TAM $1.5T 2020 -> $2.25T 2025

Competitors

Primary competition:

Fast fashion companies

Shein, Uniqlo, Zara, H&M, and Boohoo have combined market cap of $204.3B, with total market annual sales of $200B.

Secondary competition:

M2M brands (Indocino, Articles of Style)

Direct to Consumer brands (Everlane, Stitch Fix, Allbirds)

Incumbent Big Fashion (Nike, LV, Adidas, Lulu, Prada, Levis - $109B combined market cap)

Knitting machine makers: Kniterate ($4M valuation), Shima Seiki ($574M market cap)

Competitive Advantages

Why would a normal person buy our clothes?

It’s faster: by “faster”, I actually mean in design time vs “fast fashion”. H&M churns out 500 designs per week with a turnaround time of days. Good 3D knitting design tools + the local supply chain would reduce the turnaround time to hours, allowing an order of magnitude increase in weekly throughput. Better reactivity means more fashionable clothing means more sales.

Clothes are made to measure: 3D knitting is unique because every design can be computationally form fitted to every person. No more guessing “small/medium/large”. Everyone provides measurements and every purchase is guaranteed to fit perfectly.

It’s more sustainable: 3D knitted clothing uses ~35% less fabric than traditional weave & sew because you don’t have waste from the edges of panels. On top of this, you could theoretically add on mechanical unknitting (reducing clothes back into thread) as an order of magnitude increase in sustainability.

It has inherent branding advantages: I don’t know anything about marketing, so take this with a grain of salt. But, I think there are some really unique branding opportunities: sustainability, morality (no more sweat shops), bringing manufacturing back to America, and sticking it to the man / overturning the established order of global fast fashion.

Why would a normal person buy our knitting machine?

It’s cheaper: at an average $20 purchase price and the American average buy rate of one item every 5 days, a $1000 machine breaks even on value in 250 days. Yarn cost is trivial. If you factor in one needle breaking per run, at $10 per needle this changes to 500 days. This would improve as the knitting machines improve, breaking less needles.

It’s easier: downloading a design from the internet and instantly printing it is simply a better fulfillment experience than waiting 2 days to receive an online shipment or traveling to a store to buy an item

+ the other advantages mentioned above for clothes!

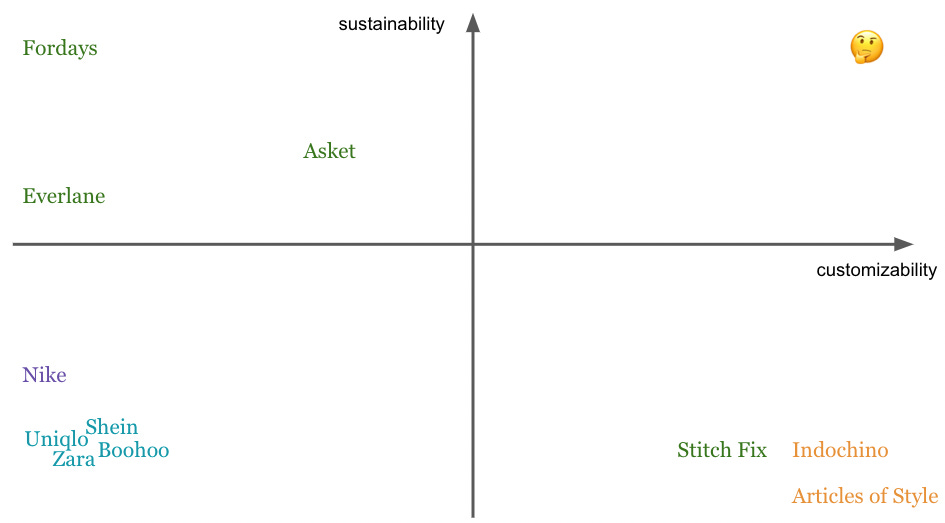

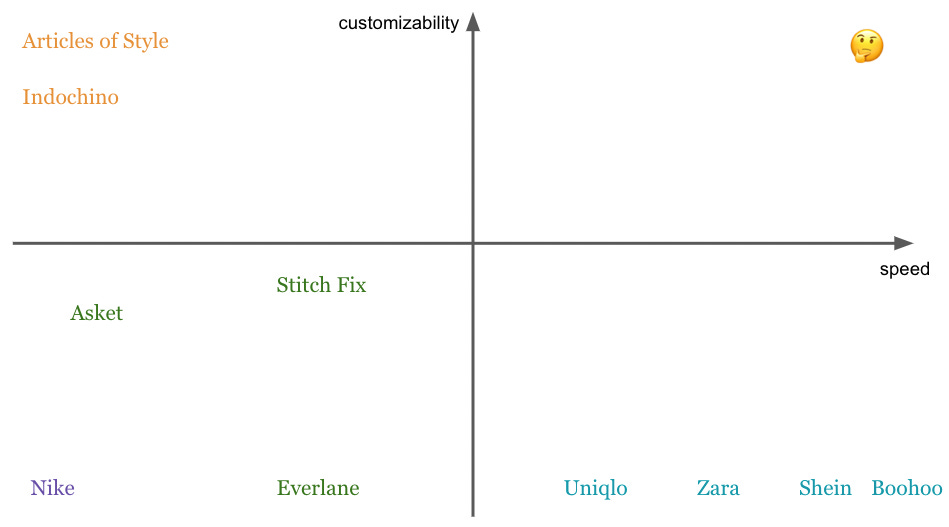

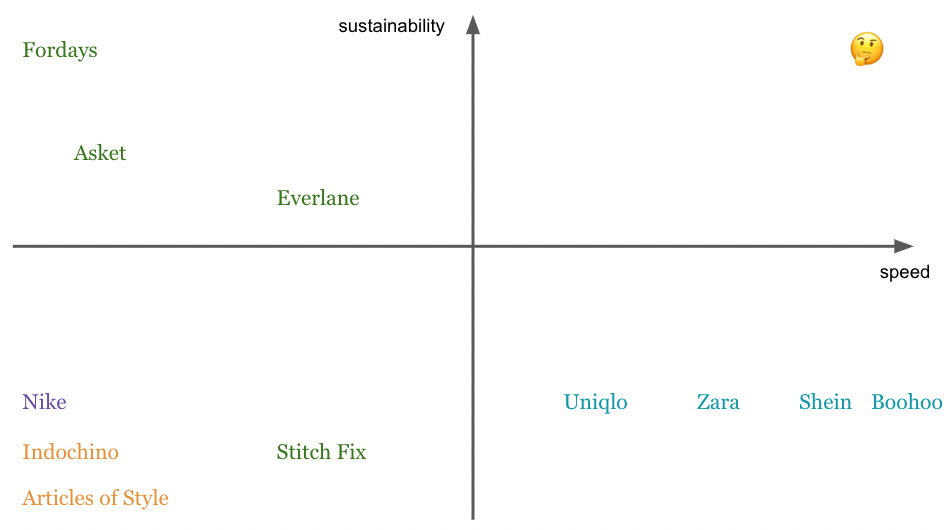

Here are some consultant-y charts to summarize the above points vs main competitors:

Competitive Disadvantages

There are some critical shortcomings here though, even assuming all the tech works:

No established brand - needs to be built up from nothing

No economies of scale - must charge higher prices, build up fulfillment and supply chain

People like to feel fabrics before they buy, so the online-only model may not work so well

Failure Modes

On top of the disadvantages, there are myriad ways this could go wrong:

Technical failure

Knitting machines have fundamental inability to hit consumer price point ($1-5k)

Knitting machines don’t actually improve in capability to be able to print most types of clothing, remaining niche

Unknitting can’t be done in a reasonable way (too annoying for customer, thread can’t be reclaimed properly, etc)

Quality failure

Quality fails to meet the standards of competition (e.g. dresses aren’t as good as other luxury price point dresses). As a mitigation strategy, we could potentially hand alter the machine output to ensure perfection / tide over until technical gaps can be bridged, but this would hurt margins

Marketing failure

Inability to establish a respected brand, leading to weak sales

Inability to establish capital inflow to enable R&D flywheel

Product failure

Inability to design desirable clothing that drives sales

Inability to design a significantly better knitted clothing design interface

Legal failure

Inability to create a legal moat for specific competitive advantages (M2M, unknitting, design software)

Legal pressure from IP owners claiming rights to knitwear technology

People failure

Self collapse from inability to execute (while the most mundane, it has to be said; this is the most common reason for startup failure)

Go to Market

In order to get started, we need to understand the solution space for knitwear, and pick a first product to sell.

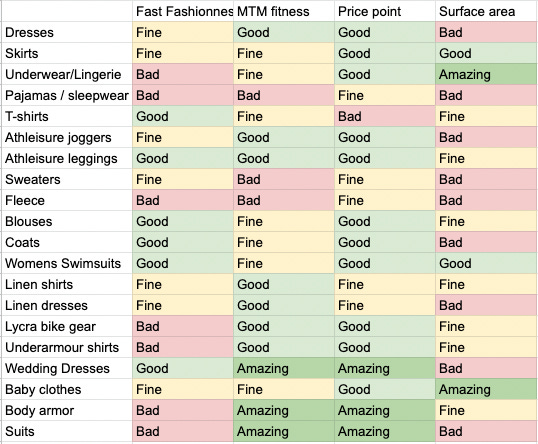

Some evaluation criteria:

Fast fashion fitness - the ability of the clothing item to be trendy / drive sales by reacting to some new trend (e.g. t-shirts good, bras bad)

MTM fitness - benefit that the clothing item gets from being made to measure. (e.g. suits good, sweaters bad)

Price point - item usually sells at a high price point (e.g. wedding dresses good, t-shirts bad)

Surface area - item prints quickly (e.g. baby clothes good, dresses bad)

Material + Gauge compatibility - material needs to be supported by knitting machine thread density requirements, and be fit for selling year-round (e.g. masks good, silk bad)

And here are some extremely cursory evaluations on some options:

Staffing + Funding

Pre-seed

$200k, buy machines, do experimentation

Seed

Headcount - $980k per year

Founders x 2 - $100k

Hardware x 2 - $200k

Software x 2 - $200k

Clothing design x 0.5 - $50k

Marketing x 3 - $200k

Legal x 0.5 - $100k

Support x 1 - $70k

Tailoring x 2 - $60k

Material investment - $200k, additional machines

Other costs (office, benefits, etc): my uninformed estimate - $500k per year

Burn Rate: 2 - 3 years to reach Phase 2

Target Raise: $4.64M seed round required

Other Expansion Ideas

Interesting ways to go completely different directions abound:

Clothing designs will be treated like software, so DRM will be needed to protect IP. NFTs fit perfectly for this, and could be directly read from the machines.

Theoretically, you could unknit a piece of clothing. Unknitting would increase the sustainability advantage by an order of magnitude. Of the four atomic operations of knitting (knit, tuck, transfer, split) all four are mechanically reversible. However, there are three auxiliary operations that are difficult to reverse: drop, in, and out. The basic issue is that when a thread is dropped by a needle, the reverse is that it needs to be picked up, which is complex. I think it’s theoretically possible, but difficult.

Medical applications - knitting contours can be used to make scaffolds for tissue regeneration

Structural elements - knitted contours can be coated with resin to form structural pieces that could go into cars, houses, sculptures, etc

Carbon nanotubes - the newest way to manufacture carbon nanotubes at scale is actually to knit them. These threads could be used to create conductive weaves, or incredibly strong nets.

Next Steps

I’ve gotten a ton of valuable feedback from friends already - if you’re one of them, thank you so much! I’d love to hear more.

I have some very important questions to answer to move forward on this:

Material / gauge analysis problem - I need to talk to a lot of people and experiment to see what can fabrics can realistically be used on these machines. If in fact only sweater gauge material can be knitted, that probably kills this strategy.

First product choice - as mentioned above.

Financial analysis - what are the unit economics at each stage, and how does needle breakage cost affect them? Will needle breakage improve with R&D?

Cofounder - I would likely need to partner with a cofounder who understands the fashion industry well, can design and market clothing, and potentially has made a direct-to-consumer brand already.

Outside of this specific strategy, I’d like to analyze B2B for supply chain and B2B2C for software as alternate business models.

To close out this post, people who know me well will find it hilarious that this is what I’m considering working on. I am not a fashionable person; truly, this is a massive understatement. You could probably describe my style as “focused utilitarian” 🙄 Isn’t it hopelessly naive to think a jogger-wearing technologist could make an impact on the world of fashion? Yes. Probably. I guess, wouldn’t it be fun to find out?

"Computational Knitting" has been a profitable technology since 1987. The world and specifically the US, is just waking up to the capabilities because of Flyknit footwear and a small group of people who know this technology really well. This technology was much more prevalent in Europe, specifically the UK, France, Italy and Germany which made fully fashioned products since the 1500 and electronically since the later 1880's. What we have today is a two tier flat knitting industry. Stoll has three computers on every machine, direct selection, and electro-magnetic needle selection, and all the other machine builders use monitors, rocker jacks, and a server to distribute data to machinery, including the Shima machine you are showing.

The 3D knitting machinery that you are showing can ONLY knit jersey based fabrics in half-gauge fabric. They are not user friendly so far and take the top minds in the world to program over hundreds of hours to make basic styles. Production is at least 3 times that of fully fashioned full gauge fabrics Damages are rampant on the 3D and all the yarns must be perfect and not run out. On the face of it, this technology looks great to people who know computers, but it is nothing like printing or 3D printing. Fibers have a life, yarns have a structure. There are so many variables that make this a series of several sciences that a user must understand in advance, rather than plug and play like a 3D printer.

On another note, not one company has made this technology profitably since it debuted in 1996, including Uniglo that had Shima in house for 3 years. The people who made for Ministry of Supply and others went bankrupt. Why/ A couple of reasons: 1) too many people listen to the machine builder sales people, who have never made anything; 2) people who code underestimate what this takes and that real life takes place outside of the computer and on the machine> Rarely does what is on the computer screen ever look like what comes from the machinery. 3) Textiles is a science that takes years to learn the intricacies of various technologies it is not one size fits all or something to learn fast like in the movie The Matrix; 4) It takes a lot of knowledge that few teach any more to make these 3D and 4D projects. Newbies and startups want instant gratification.

To get things like this automated means someone needs to think this all our and program every option in advance - very much like AI. Most new people to this industry don't want to pay what it takes to plan all this out and think this is like fashion. it is not anything like fashion development. But it does not stop many people new to this industry to think they can learn this technology in 2 weeks or 2 months, while they treat experts like me as if our knowledge is as common sewing, and that we should just make their stuff for a few hundred dollars, so that they can go off and make millions or billions.

This technology is not as easy as the sales people selling the machines say. It takes woeeks to make one product, if you are an expert; months if you are good, and never if you you don't put in the time to learn.

It takes years if not a decade or more to master techncial 3D and 4D knitting, and still in that time, one might not see everything. Been doing this a long time and rarely had the same project type twice. Sure, people can cut and paste once they have a master to copy, but comng up with the original is where all the knowledge comes into being for a first to market product.

Machine gauge and materials are a science that takes textile engineering and knitting expertise - no short cuts here. Needle breakages is negligible if the machiner are oiled and maintained properly, tensions are not ttoo tight or too lose and the machine speed is appropriate for the structures and transfering. As far as financials, IMHO you are off by a couple zeros.